Graphene Mass Production

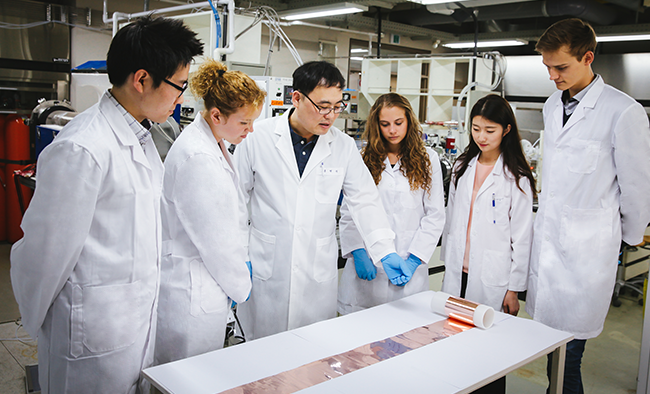

CVD-Graphene Mass Production at Graphene SquareContinuous R2R-CVD graphene synthesis system at Graphene Square

Graphene Square is a pioneer in mass production of high quality graphene with patented (R2R) Chemical Vapor Deposition technology, where a system of precisely control synthesis parameters under continuous operation is designed to yield uniform monolayer graphene on a large area. (hundreds of meters scale long graphene film.) For example, our 8 inch size R2R Chemical Vapor Deposition system results in ten times increase in production yield in comparison with a batch type CVD synthesis of the same size: > Batch type CVD : 40 batches per day → 20 m2/day > Continuous R2R-CVD : 0.20 m2/min → 288 m2/day > More than 10 times increase in productivity. In addition, Graphene Square is also a pioneer in a patented R2R dry transfer method, where graphene synthesized on metal foils can be transferred on variety of substrates. [1].

VIEW CVD EQUIPMENT-

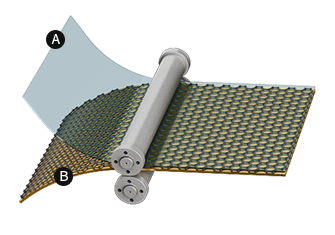

A. Polymer support B. Graphene on Cu foil

-

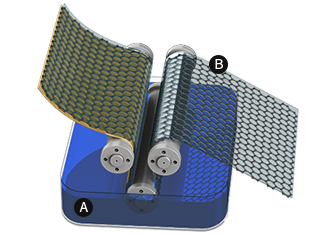

A. Cu etchant B. Graphene on polymer support

-

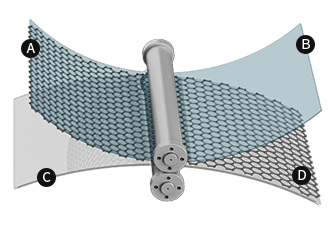

A. Graphene on polymer support B. Released polymer support C. Target substrate D. Graphene on target

S. Bae*, H. Kim* et al. Roll-to-roll production of 30 inch graphene films for transparent electrodes, Nature Nanotech. 2010, 5, 574

Other Graphene Mass Production Technologies

Most of the mass production process is based upon top down approach, where natural or synthetic graphite flake are exfoliated into multilayers or even single layer graphene flakes.

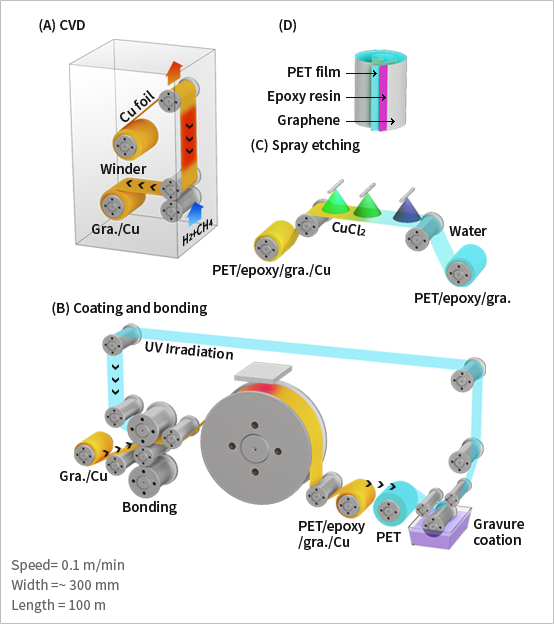

R2R CVD graphene synthesis and transfer system developed by Sony[2] Kobayashi, T.; Bando, M.; Kimura, N.; Shimizu, K.; Kadono, K.; Umezu, N.; Miyahara, K.; Hayazaki, S.; Nagai, S.; Mizuguchi, Y.; Murakami, Y.; Hobara, D. Production of a 100-m-long high-quality graphene transparent conductive film by roll-to-roll chemical vapor deposition and transfer process. Appl. Phys. Lett. 2013, 102, 023112.

R2R CVD graphene synthesis and transfer system developed by Sony[2] Kobayashi, T.; Bando, M.; Kimura, N.; Shimizu, K.; Kadono, K.; Umezu, N.; Miyahara, K.; Hayazaki, S.; Nagai, S.; Mizuguchi, Y.; Murakami, Y.; Hobara, D. Production of a 100-m-long high-quality graphene transparent conductive film by roll-to-roll chemical vapor deposition and transfer process. Appl. Phys. Lett. 2013, 102, 023112.

This method often yields multilayers graphene (or RGO) in flake types which having lateral length in the range of several hundred nanometers to several micrometers. It is suitable for mass production of graphene flake at relative low production cost and can yield large quantity of graphene flake for a variety of application, where high purity is not required such as fillers for polymer nanocomposite, coating, conductive inks& paste, energy storage (electrode for Lithium ion, Lithium sulfide, Lithium-air batteries and supercapacitors) applications...etc. Following this approach, a number graphene flake producing companies are appeared on commercialization roadmap and news media such as Angstron Materials, Vorbeck Materials, XG Sciences Inc (US), Grafoid Inc (Canada), Haydale Inc (UK), GRAnPH Nanotec Inc (Spain), Xiamen Knano Graphene Technology Corporation Limited (China)..etc In another way, high quality, large area, controlled number of graphene layers (single layer) for electronics application are relied on Chemical Vapor Deposition using carbon precursors at high temperature on metal catalyst (Bottom-up approach). This method is the most potential method for mass production of high purity graphene for electronic applications such as flexible transparent conductive electrode for displays, touch screen, sensors, wearable electrics, transparent heater, acoustic device, gas barrier, EMI shielding application…

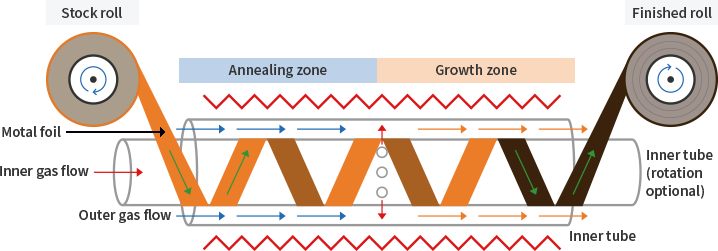

Roll-to-Roll concentric tube CVD developed at university of Michigan and Massachusetts Institute of Technology [3] Polsen, E.S.; McNerny, D.Q.; Viswanath, B.; Pattinson, S.W.; John Hart, A. High-speed roll-to-roll manufacturing of graphene using a concentric tube CVD reactor.آ Scientific Reports,آ 2015, 5, 10257

Roll-to-Roll concentric tube CVD developed at university of Michigan and Massachusetts Institute of Technology [3] Polsen, E.S.; McNerny, D.Q.; Viswanath, B.; Pattinson, S.W.; John Hart, A. High-speed roll-to-roll manufacturing of graphene using a concentric tube CVD reactor.آ Scientific Reports,آ 2015, 5, 10257

Following this approach, a list of research leading institutions and companies are IBM, Massacchusetts Institute of Technology, University of Michigan, Seoul National University-Graphene Square Inc (Korea), Hanwha Techwin (Korea), Sony (Japan), Samsung Electronic in collaborating with Sungkyunkwan University (SKKU-Korea), ACS materials inc (US), Graphenea Inc (Spain), Graphene Frontiers (US), Applied graphene materials (Duham University-UK)…ect.