You can see the image to the left or right by turning the equipment

Related Key Patents (Registered)

| No. | Reg. Date(Korea) | Title | Reg. Date(Korea) | Reg. No (International) |

|---|---|---|---|---|

| 1 | 2013-02-12 | Roll-to-roll doping method of graphene film, and doped graphene film | 10-1234180 | US 8926854 B2 |

| 2 | 2013-05-02 | Roll-to-roll transfer method of graphene, graphene roll produced by the method, and roll-to-roll transfer equipment for graphene | 10-1262327 | US 8916057 B2 CN 102656016 B JP 5707628 B2 JP 5787113 B2 |

| 3 | 2014-03-03 | Graphene roll-to-roll coating apparatus and graphene roll-to-roll coating method using the same | 10-1371286 | JP 5424210 B2 |

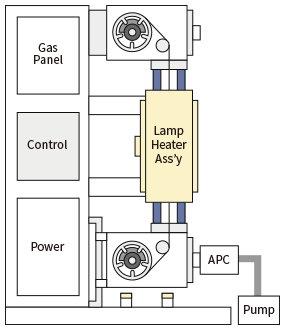

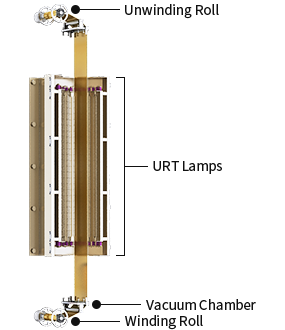

Roll to Roll CVD Concept

| The internal system | ||

|---|---|---|

|

|

APC pressure control process Heater 8Zone developed process Roll to Roll transfer system

APC pressure control process Heater 8Zone developed process Roll to Roll transfer system

|

-

-

Specifications

Construction...

-

Consumable Parts

K-type Thermocouple (Option : R-type)

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

-

Specifications

-

Facility Requirements

Construction...

-

Layout

-

Standard Warranty

Each system is delivered with a standard warranty that covers all parts-excluding quartzware and O-rings- for one (1) year from the date of commissioning of the system. Any defects in materials or workmanship during the warranty period will be fixed or replaced free of charge to the customer. *Note: Any unauthorized modification of the system will result in the voiding of warranty.

-

Delivery Time & Shipping Policy

The delivery time is estimated to be 8-12 weeks upon receipt of order. Graphene Square Inc. ships each system to the customer site by Incoterms CIP (Carriage & Insurance Paid) air freight direct from its factory in Korea.

-

Equipment Purchasing Process

-

1

Request Quote

-

2

Confirm Quote Details with Purchase Order

-

3

Invoice / Payment

Send Invoice and Payment information

-

4

System Production Initiated with Down Payment

Training program offered

-

5

Equipment Operation Test / Export packaging & shipment

Upon completion of system production, factory operation test performed.

-

6

Express Air Shipment & Delivery

Estimated delivery

вҖ“ 4 business days

-

1

-

FAQ

Construction...