Vapor Deposition The main Thermal CVD technology involves adding gases to the pressurized reactor at high temperature of about 1,000в„ғ where thin film is synthesized onto substrates.

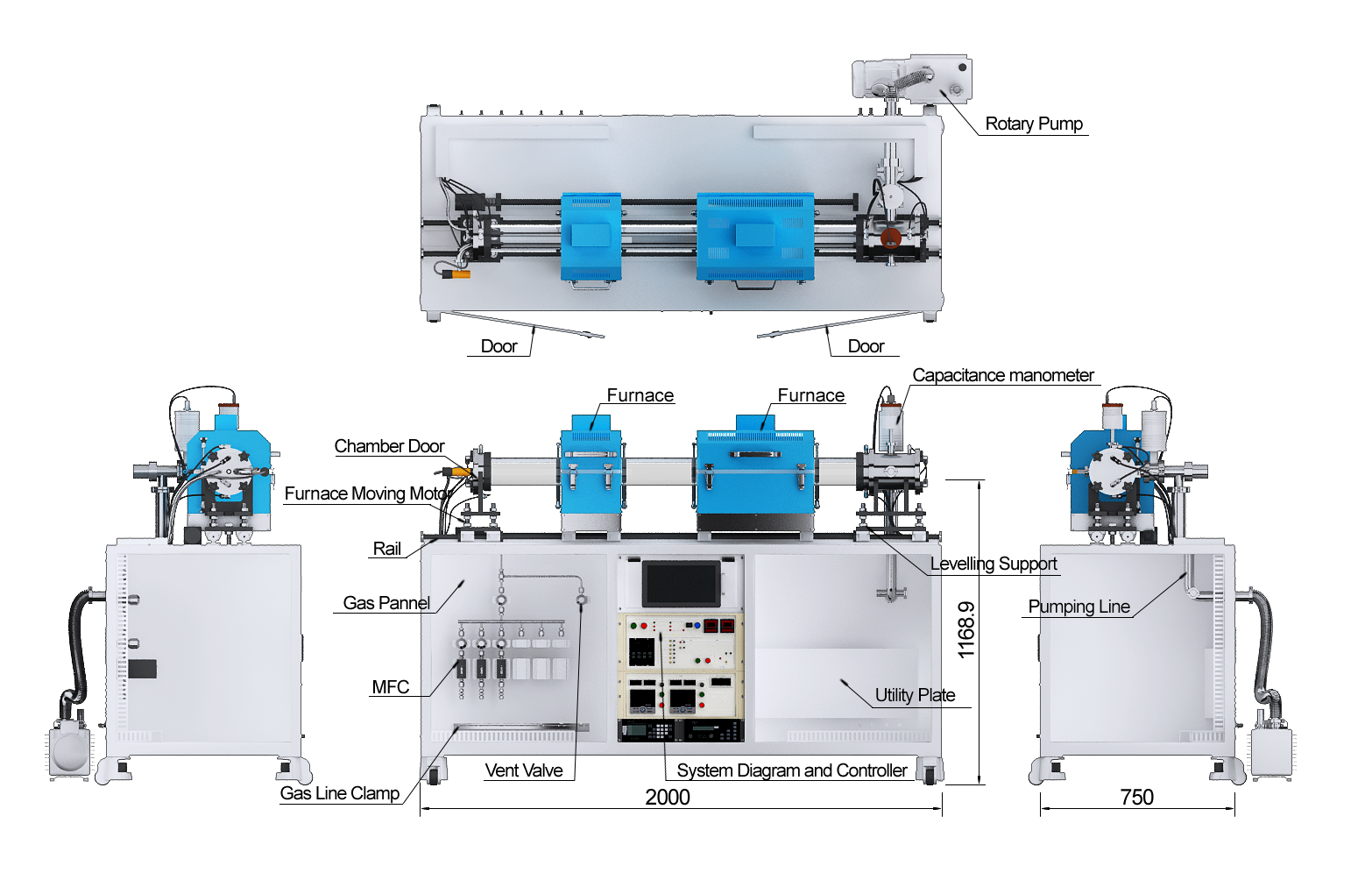

- Size (mm) : 2300(W) x 1770(H) x 750(D)

- Advanced Computer Controlled Automatic System

- Optimized for graphene, CNT, h-BN TMDC growth

- Water-cooled end chambers and doors

- Process Temperature: ~1,100 в„ғ

- Uniformity of Film Thickness : вүӨ+-3%

- Testing Uniformity : вүӨ+-3%

- Movable furnace method is our unique knowhow for fast heating fast cooling of the sample.

You can see the image to the left or right by turning the equipment

Shut-off System(Option) The safety cabinet is a total enclosure for the system with an emergency shut-off button. It can protect the user(s) in dangerous situations.

High Quality Graphene

and Other 2D Materials Able to support growth of high quality

graphene as well as other 2D materials with

safety features.

-

-

Standard features

-

Thermal CVD Auto Operation system

-

Both End chamber(Stainess) - All parts cooling by water

Quartz Main chamber

Gas control unit ( Mass flow controller) - 3channel standard

-

340liter/min Oil rotary pump

-

Pneumatic On/off valve with Down stream Auto pressure control Throttle valve

with controller -

Programmable Temperature controller

-

High Temperature Furnace(Max1200в„ғ)

-

Rapid Cooling system by furnace moving

-

Atmospheric and Vacuum Processing

-

Anti-contamination system by inner tube

-

Vacuum gauge unit(Capacitance/Convectron)

1 year warranty

-

On-site install and training

-

System Program ( Auto processing system)

Furnace for source evaporation

-

Safety interlock system(Water / Air)

-

-

Options

-

Max temp 1500в„ғ Furnace by SIC source

-

Rapid thermal processing furnace by IR lamp source

MF power induction heating process Max temp 1600в„ғ

MFC(Mass flow controller) addition total 12channel

-

Dry vacuum pump ( Scroll / booster / industry)

-

Gas Safety interlock system for gas leak

RF plasma ( ICP type )

Tungsten filament gas source cracking

-

High Vacuum processing option

(Pump/Gauge/valve unit) -

Source delivery system ( Bubbler / Gas / Solid )

-

System Utility ( Chiller / scrubber / gas cabinet )

-

-

Consumable parts

K-type Thermocouple (Option : R-type)

Furnace heating element (Furnace repair)

Vacuum sensor

Oil in Rotary Oil Pump

O-ring

Quartz tube

-

Standard features

-

Facility requirements

Construction...

-

Layout

-

Standard Warranty

Each system is delivered with a limited warranty that covers parts, excluding consumable and wearable parts such as quartz ware and O-rings, for one (1) year from the date of commissioning of the system. Any parts confirmed to be defective will be sent to customer for replacement during the warranty period. *Note: Any unauthorized modification of the system will result in the voiding of warranty.

-

Delivery Time & Shipping Policy

The delivery time is estimated to be 8-12 weeks upon receipt of order. Graphene Square Inc. ships each system to the customer site by Incoterms CIP (Carriage & Insurance Paid) air freight direct from its factory in Korea.

-

Equipment Purchasing Process

-

1

Request Quote

-

2

Confirm Quote Details with Purchase Order

-

3

Invoice / Payment

Send Invoice and Payment information

-

4

System Production Initiated with Down Payment

Training program offered

-

5

Equipment Operation Test / Export packaging & shipment

Upon completion of system production, factory operation test performed.

-

6

Express Air Shipment & Delivery

Estimated delivery

вҖ“ 4 business days

-

1

-

FAQ

Construction...