We aspire to provide the best quality products

Features

Size (mm): 2300(W) x 1770(H) x 750(D)

Up to 10 gases 3 MO sources for gas-phase synthesis.

Motor-controlled movable heater for fast heating cooling (patented).

Fully computer-controlled programmable recipes.

TCVD100 platform: Proven performance for ~100 systems for more than 5 years.

Invited training for full sample preparation processes from synthesis, etching, transfer.

Supply of high-quality source materials.

1 year warranty included (2 year extended warranty available)

CVD chambers connected to a Glove Box. Free from air exposure.

Estimates

Estimates

Premium Custom Design Dual CVD System with a Glove Box

Chemical vapor deposition (CVD) system for the syntheses of 2D materials at scales from a chip to a wafer, including the synthesis of graphene, h-BN, TMDCs on various substrates by use of gas-phase or solid precursors metal-organic (MO) sources. The synthesized samples can be transferred to a glove box filled with inert gases for further processes without exposure to air environment.

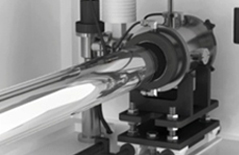

Furnace ( Heater )

TCVD Controller Panel

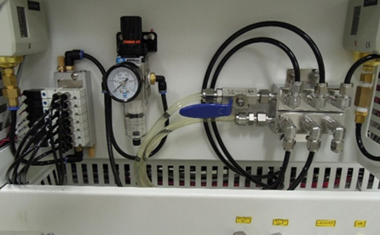

TCVD Vacuum/Gas Control

Rotary pump - W2V40 (*RP)

Pumping speed: 400 l/min

Pump oil: fomblin oil

Rotary pump auto vent valve

240 V AC (Normal open type)

Angle valve - NW 40

port, Pneumatic type

MFC (Atovac AFC500)

a. MFC1 : Ar (1000 SCCM )

b. MFC2 : CH4 (200 SCCM )

c. MFC3 : H2 (100 SCCM )

Pneumatic Valve

a. Ar input valve

b. CH4 input valve

c. H2 input valve

d. Vent valve

e. Main Gas input valve

Gas Module

Utility Area

Sample Loading End Chamber

Gas Supply End Chamber

Electric Power Panel

TCVD Error Alarm Singnal

TCVD Service Tool Box Components

| CVD Reactor | Dual Tube type 4 inch diameter quartz. Remote Microwave Plasma Module. Connected to a Glove Box. |

| Substrate Size | Lateral ion of 10 mm to < 4 inch wafers possible. )Loading frames for small samples) Rolled metallic foils can be loaded to synthesize A4 sized or larger 2D materials. |

| Heating | Dual-zone heater controller for graphene/h-BN synthesis. Single-zone precursor heater Dual-zone deposition heater for TMDC synthesis. The heaters are movable along two rails the distance can be motor-controlled, enabling 10ºC/sec or faster temperature change rate. |

| Base Pressure | 10-5 mbar (depending on the dryness of source) |

| Operating Pressure | 10-3 mbar - 1 bar |

| Precursor | Max 10 gas lines (ex. CH4, C2H4, NH3, B2H6, Ar, H2, H2S, H2Se, N2, O2) + 2 extra ports. Metal oxide sources of various transition metals placed in Heat Zone 1 for solid source growth. |

| Other metal organic (MO) sources |

Extra 3 Metal-Organic Source Injection Ports are included. (ex Mo(CO)6, Fe(CO)5) Low-T cold trap for residual sources |

| Flow control | Precursor gases: 0.1 - 10 sccm Other gases: 10 - 1000 sccm Automatic flow control |

| Vacuum | Turbo pump 450l/s (ISO160) < 10-6 mbar Dry scroll pump < 10-1 mbar Main Gate Valve Pneumatic type / Fore-line / roughing Angle Valve / Foamed bellows By-pass pumping adaptor, clamp & centering |

| T-measurement | Stard Thermocouple (NIR calibrated) |

| Sample switching | Position switching at sample loading stage |

| System Control | Control PC system (12" touch, dual core) Serial Network module (4-ch) Remote IO module (RS485) System base programming / System recipe control module / System date file save module Software upgrade support Gas valve, angle valve Open/Close / Rotary pump On/Off switch / Main power On/Off switch Cooling water & air pressure switch |