We aspire to provide the best quality products

Features

Size(mm): 1750(W) x 1585(H) x 750(D)

Advanced Semi-Auto System

Optimized for graphene, CNT, h-BN TMDC growth

Water-cooled end chambers doors

Process Temperature: ~1,100°C

Uniformity of Film Thickness: ≤+-3%

Testing Uniformity: ≤+-3%

Movable furnace method is our unique knowhow for fast heating

fast cooling of the sample

Standard safety box

Columbia University TA100 (4inch)

University of North Texas TCVD 100A

UCLA TCVD 100mm

Harvard University TCVD 100mm

Boston University TCVD 100mm

University of Cambridge TA100 (4inch) (UK)

University of Cambridge TCVD 100A (4inch) (UK)

Norwegian University of Science Technology (Norway)

University of Bari TA100 (4inch) (Italy)

I-TRIX CORP TCVD 100A (Japan)

King Abdullah Uuiversity TCVD System(2inch) (Saudi Arabia)

Customization

Columbia university (USA) TA100(4inch)

University of Cambridge(UK) TA100(4inch)

I-TRIX CORP (Japan) TCVD 100A

University of Bari (Italy) TA100(4inch)

University of North Texas TCVD 100A

Norwegian University of Science Technology (Norway)

KING ABDULLAH UNIVERSITY(Saudi Arabia) TCVD System(2inch)

University of Cambridge (UK) TCVD 100A(4inch)

UCLA (US) TCVD 100mm

Harvard University (US) TCVD 100mm

Boston University (US) TCVD 100mm

Estimates

Estimates

Stard 4-Inch Thermal CVD System with a Safety Cabinet

TCVD-100A is a very sophisticated cost effective CVD system that can be equipped with semi-automatic or fully programmable gas-flow temperature control modules. It is the most ideal equipment for the synthesis of high quality graphene h-BNs, which can be easily extended to various 2D materials synthesis. The safety cabinet that covers the whole system protects users from any hazardous event, the emergency stop button will ensure the safety even further.

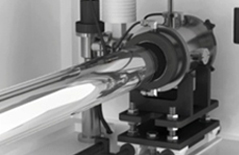

Furnace ( Heater )

TCVD Controller Panel

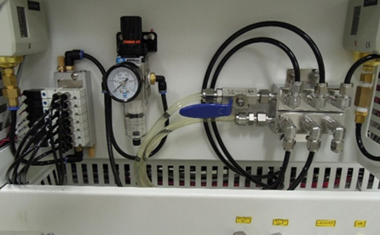

TCVD Vacuum/Gas Control

Rotary pump - W2V40 (*RP)

Pumping speed: 400 l/min

Pump oil: fomblin oil

Rotary pump auto vent valve

240 V AC (Normal open type)

Angle valve - NW 40

port, Pneumatic type

MFC (Atovac AFC500)

a. MFC1 : Ar (1000 SCCM )

b. MFC2 : CH4 (200 SCCM )

c. MFC3 : H2 (100 SCCM )

Pneumatic Valve

a. Ar input valve

b. CH4 input valve

c. H2 input valve

d. Vent valve

e. Main Gas input valve

Gas Module

Utility Area

Sample Loading End Chamber

Gas Supply End Chamber

Electric Power Panel

TCVD Error Alarm Singnal

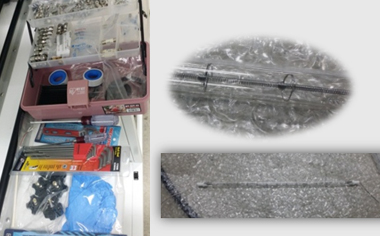

TCVD Service Tool Box Components

| CVD Reactor | Tube type 4 inch diameter quartz |

| Substrate Size | Lateral ion of 10 mm to <4 inch wafers possible. (Loading frames for small samples) Rolled metallic foils can be loaded to synthesize A4 sized or larger 2D materials. |

| Heating | Dual-zone heater controller can be used for graphene/h-BN synthesis. Single-zone precursor heater Dual-zone deposition heater can be used for TMDC synthesis. The heaters are movable along two rails the distance can be motor-controlled, enabling 10°C/sec or faster temperature change rate. |

| Base Pressure | ~ 10-5 mbar (depending on the dryness of source) |

| Operating Pressure | 10-3 mbar - 1 bar |

| Precursor gases | Max 10 gas lines (ex. CH4, C2H4, NH3, B2H6, Ar, H2, H2S, H2Se, N2, O2) + 2 extra ports Metal oxide sources of various transition metals placed in Heat Zone 1 for solid source growth |

| Other metal organic (MO) sources |

Extra 3 Metal-Organic Source Injection Ports are included. (ex Mo(CO)6, Fe(CO)5) Low-T cold trap for residual sources |

| Flow control | Precursor gases: 0.1 - 10 sccm Other gases: 10 - 1000 sccm Automatic flow control |

| Vacuum | Turbo pump 450l/s (ISO160) < 10-6 mbar Dry scroll pump < 10-1 mbar Main Gate Valve Pneumatic type / Fore-line / roughing Angle Valve / Foamed bellows By-pass pumping adaptor, clamp & centering |

| T-measurement | Standard Thermocouple (NIR calibrated) |

| Sample switching | Position switching at sample loading stage |

| System Control | Control PC system (12" touch, dual core) Serial Network module (4-ch) Remote IO module (RS485) System base programming / System recipe control module / System date file save module Software upgrade support Gas valve, angle valve Open/Close / Rotary pump On/Off switch / Main power On/Off switch Cooling water & air pressure switch |